When Reynolds Packaging needed a reliable, energy-efficient solution to manage air emissions and recover oil from its aluminum rolling mill operations, they turned to RCM Thermal Kinetics. The result? A fully modular, automated process plant that exceeded expectations in both performance and delivery timeline.

In just nine months, RCM Thermal Kinetics designed, built, and delivered a high-performance system that included an emissions control scrubber and a high-vacuum distillation process—ensuring the plant consistently met state air quality standards of ≤50 ppm. In fact, the system regularly achieved results under 25 ppm.

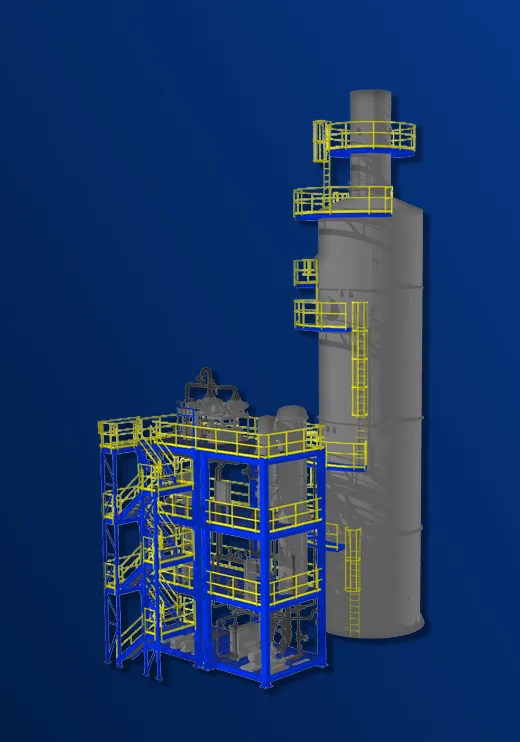

A Modular, Automated Solution

One of the key achievements of this project was the delivery of a fully modular, automatic process plant. All critical components—equipment, high-vacuum distillation system, and PLC automation—were integrated into a compact system that featured:

- Push-button start and stop functionality

- Minimal operator involvement

- Full automation of startup, shutdown, and emergency sequences

The flexible design allowed Reynolds Packaging to respond to evolving needs throughout the project, including requests for more operational automation, which RCM TK implemented during the final construction stages.

Meeting and Exceeding Emissions Targets

Clean air emissions were a primary goal. The custom-engineered system not only met ASME state air quality standards but exceeded them. Operating at less than 2 mm Hg absolute pressure and 340°F, the distillation unit consistently maintained emission levels under 25 ppm—half of the allowable limit.

Overcoming Technical Challenges

No complex industrial project is without hurdles. For Reynolds Packaging, two key challenges emerged during development:

1. Mid-Project Automation Request

Originally scoped as an operator-assisted system, Reynolds requested fully automated startup and shutdown sequences partway through the project. RCM Thermal Kinetics delivered—integrating full PLC control in just a few weeks, all without disrupting the project timeline.

2. Corrosion from Oil Oxidation

During testing, high-temperature oil oxidation triggered unexpected corrosion. RCM TK’s engineering team quickly identified the issue and re-engineered aspects of the system to prevent further oxidation and corrosion—preserving both performance and system longevity.

The Outcome

This project was completed on schedule and within scope. Thanks to its success, RCM Thermal Kinetics has since delivered three additional systems to the aluminum rolling industry—solidifying its position as the market leader for emissions recovery systems in this sector across the U.S.

Why Choose RCM Thermal Kinetics?

RCM TK specializes in modular, automated process systems tailored for demanding industrial environments. With every project, we deliver:

- Full system design and construction

- Advanced automation and control integration

- On-site commissioning and startup support

- Energy-efficient, high-performance process engineering

Based in Buffalo, NY, our U.S.-based team works closely with customers to ensure responsive service, rapid problem-solving, and long-term operational success.

Want to learn how RCM TK can support your emissions, energy, or recovery system goals?

Contact us today to discuss your next project.